Ready to Get Started?

Send us information on you, your company and your project. One of our experts will respond as soon as possible.

While industrial assets are built to handle pressure, heat, and vibration over time, even the strongest, highest quality equipment eventually shows its age: shafts drift out of alignment, flanges erode, bores lose tolerance. Restoring assets to their original condition through industrial repair traditionally involved its own downtime and lost productivity, requiring disassembly, transport to a machine shop, and lengthy reinstallation.

On-site machining, also known as field machining, changes that equation. By mobilizing portable, precision tools and expert technicians directly to the equipment, operators no longer have to choose between proactive maintenance and productivity. But the real story goes deeper. While all on-site industrial repairs add another layer of convenience, TEAM’s field machining services fit into the broader TEAM360 ecosystem to protect performance, extend lifespan, and provide next-level operator confidence.

Here’s how TEAM’s unique approach amplifies field machining benefits and delivers future-proof asset reliability for our clients.

On-site machining isn’t new, but the stakes (and the technology) have evolved. What began as a workaround for emergencies has evolved into a frontline solution for modern industry. Advances in portable CNC tools, laser-tracking systems, and self-leveling platforms now enable shop-quality precision to be achieved directly in the field. During a period where industrial systems are not only growing more complex but also more interconnected, industrial repairs must avoid time-consuming and risky dismantling and reintegration processes for organizations to remain competitive.

Simply put, operators are under increasing pressure to balance uptime, safety, and cost efficiency while meeting strict regulatory and compliance demands. On-site machining delivers industrial repairs that minimize disruption, reduce risk, and ensure critical assets can be returned to service in hours rather than weeks.

According to Aberdeen Research, unplanned downtime costs industrial operators an average of $260,000 per hour, a figure that has surged nearly 60% in the past decade. At the same time, NIST reports that U.S. manufacturers spend more than $57.3 billion annually on machinery maintenance and industrial repairs, yet lose an additional $119.1 billion in preventable costs, including $18.1 billion from downtime alone.

Every wasted hour carries a price tag measured in hundreds of thousands of dollars, and the ripple effects extend far beyond the immediate cost. A single halted turbine in a power plant can jeopardize grid stability. An offline pump in a refinery can delay an entire production chain, raising safety and environmental risks. For industries where margins are tight and uptime is mission-critical (such as power generation, refining, chemicals, and manufacturing), traditional shop-based industrial repairs aren’t just inefficient; they’re a luxury operators can no longer afford.

Making the shift from traditional maintenance to on-site machining is the most intuitive way for operators to decrease downtime. Instead of dismantling, shipping, and waiting for shop work, Complex flange repairs, journal restorations, or bore machining can be executed in place, and what used to take weeks can be completed in hours. TEAM’s expertise and manpower turn field machining benefits into powerful maintenance differentiators. Here’s how:

With global coverage and one of the largest fleets of portable machines in the industry, TEAM can respond quickly to urgent needs, deploying the right equipment and expertise to minimize downtime before it escalates.

Because on-site machining is fully integrated with Inspect360, any problems uncovered during inspection can be addressed immediately, eliminating scheduling delays and turning potential issues into same-day solutions.

Backed by decades of on-site machining experience across industries, from power to petrochemicals, TEAM’s crews bring the deep field knowledge and technology needed to anticipate challenges, reduce surprises, and deliver faster, more reliable industrial repairs.

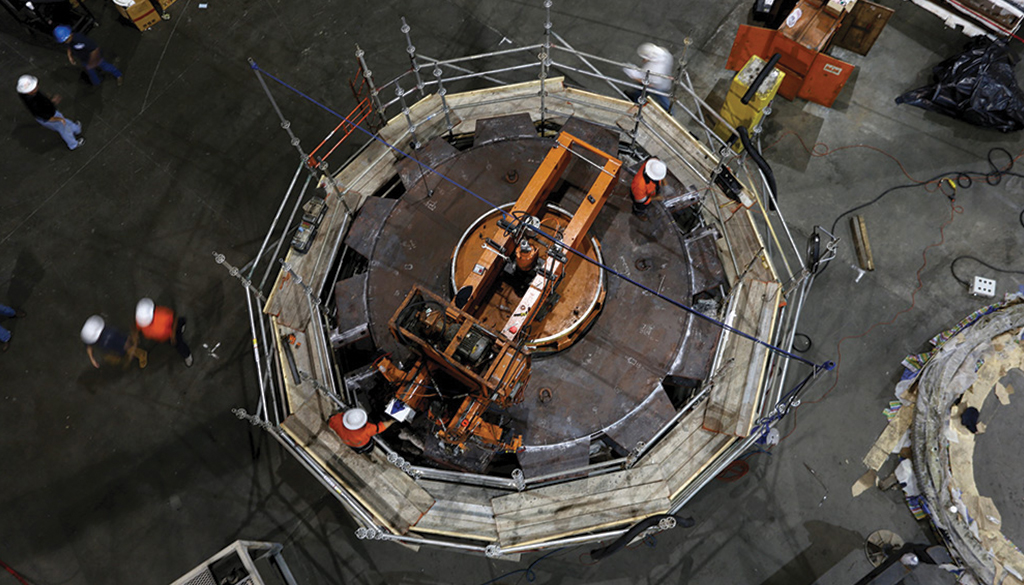

Precision isn’t negotiable. Even a minor deviation in flatness, concentricity, or roundness can set off a chain reaction of failures: accelerated wear, costly leaks, and reduced efficiency that ripple across an entire system. Traditionally, only dedicated machine shops could guarantee this level of accuracy, forcing operators into disruptive cycles of disassembly and transport. Today, however, advances in on-site machining technology completely remove risk without compromising the quality of the industrial repair. TEAM’s field machining crews can achieve millimeter- and even sub-millimeter tolerances directly on-site, delivering the kind of accuracy once reserved for stationary workshops.

Self-leveling systems ensure perfect alignment even when working on uneven foundations. Laser-tracker technology provides real-time verification of concentricity and positioning, while CNC-controlled portable mills and lathes deliver repeatable, shop-quality machining anywhere in the world. Together, these capabilities allow our TEAM to restore critical surfaces (from turbine casings to large-diameter vessel flanges) to OEM tolerances without ever removing the equipment from service. The result is faster, more reliable industrial repairs that protect performance without compromising accuracy.

Our TEAM deploys the latest generation of portable machine tools for on-site machining, backed by investment in proprietary equipment.

Precision is only as good as the hands guiding the tools. TEAM machinists pair deep OEM knowledge with in-house training, completing rigorous indoctrination and service-discipline certifications so they arrive as true specialists — not generalists.

Repairs are validated on-site with laser trackers and digital QA systems, ensuring confidence before equipment returns to service.

Explore Our Field Machining Services

Industrial systems don’t come in one size, and neither do the problems that affect them. The true strength of field machining lies in its flexibility to adapt to virtually any scale, geometry, or environment. TEAM’s capabilities cover the full spectrum of industrial repair needs: flange facing that restores sealing surfaces and prevents leaks, journal and shaft restoration to correct wear and extend the life of rotating equipment, bore machining to bring misaligned housings or worn casings back into specification, and pipe beveling that prepares critical welds.

We bring a level of critical versatility to onsite machining across every major industry. In power generation, turbines, pumps, and casings can be restored without the costly disruption of disassembly. In gas and oil, refinery and offshore equipment can be machined in place, reducing logistical hurdles and operational risks. No matter the asset or operating conditions, our TEAM has an on-site machining solution ready to restore performance and protect reliability.

From heavy-duty, large-diameter machining rigs to specialized micro-precision tools, TEAM maintains one of the most extensive portable fleets in the industry, ensuring the right setup is always available for any asset or application.

Our crews are trained and equipped to operate in the toughest conditions, whether confined spaces, offshore platforms, or harsh outdoor environments, and deliver consistent results wherever critical industrial repairs are needed.

Instead of coordinating multiple vendors for inspection, machining, and repair, operators can rely on TEAM as a single integrated partner, simplifying project management and ensuring seamless accountability from start to finish.

Disassembly isn’t just slow. It’s inherently risky. Every stage of industrial repair, from rigging and crane lifts to transport and reinstallation, introduces hazards that increase crew exposure and complicate already demanding environments. On-site machining removes those risks by keeping assets in place, reducing the need for heavy lifts, minimizing confined space entries, and limiting the number of opportunities for something to go wrong.

Just as importantly, onsite machining simplifies the project itself. Rather than coordinating multiple vendors for teardown, machining, and reassembly (and navigating all the scheduling conflicts, handoffs, and accountability gaps that come it) TEAM manages the entire process under one roof. One of the most critical field machining benefits? A streamlined workflow that delivers faster execution and reduces risk with one accountable partner from start to finish.

Every crew follows rigorous, industry-honed safety protocols designed to minimize exposure, reduce handling risks, and maintain compliance in even the most demanding environments.

TEAM machinists work directly alongside Inspect360 and Repair360 specialists, ensuring inspection findings flow immediately into precision machining and repair without delays or handoffs.

With TEAM managing the full process, clients avoid coordination headaches and gain a single accountable partner they can trust.

TEAM doesn’t treat on-site machining as a one-off fix. Instead, it’s embedded in a lifecycle strategy where inspection, repair, and digital oversight are tightly connected to deliver lasting results.

The process starts with Inspect360, which identifies wear, misalignment, or cracks before they escalate into failure. When machining is required, Repair360 crews restore precision in real time, ensuring components are brought back to OEM-level tolerances without leaving the field. Detect360 verifies that no secondary leaks or weaknesses compromise the repair. Operators can further elevate the strength and reliability of their assets with Heat360, which leverages heat treatment to ensure repairs last longer. Finally, the entire process is documented through OneInsight, which provides a transparent digital record for compliance, quality assurance, and future maintenance planning.

The most important field machining benefit TEAM offers? A coordinated ecosystem that strengthens asset reliability, reduces long-term risk, and supports digital transformation goals.

TEAM360 ensures machining is part of a comprehensive lifecycle strategy, connecting inspection, repair, and digital oversight to strengthen long-term asset performance.

Every repair is documented and analyzed through OneInsight, providing operators with transparent records, actionable insights, and smarter planning for compliance and future maintenance cycles.

By integrating machining into a broader ecosystem of inspection, leak detection, and repair, TEAM reduces repeat issues, improves overall asset integrity, and extends equipment lifespan across industries.

On-site machining has become a cornerstone of modern asset strategy because uptime is everything. It allows operators to perform precision industrial repairs where equipment stands — restoring OEM tolerances, extending service life, and protecting productivity without the disruption of dismantling or transport.

The real advantage, however, comes from TEAM’s integrated approach. Backed by decades of expertise, the industry’s largest fleet of portable machine tools, and the strength of the TEAM360 ecosystem, TEAM turns field machining benefits into long-term performance gains.

When precision cannot wait and reliability cannot be compromised, our TEAM sets the standard for industrial repair. Our on-site machining solutions provide clients with more than a quick repair. We’re a hands-on partner who always gets the job done faster, safer, and more effectively than traditional repairs and other on-site machining providers.

See how TEAM Inc. is raising the bar for environmental stewardship, safety, governance, and community impact. Our 2024 Sustainability Profile details the practices, data, and real-world results behind our commitment to a safer, more sustainable future. Download the full report today to learn how our people, processes, and partnerships keep critical industries moving responsibly — and why sustainability is at the core of everything we do.

View the 2024 ProfileSend us information on you, your company and your project. One of our experts will respond as soon as possible.