In the complex network of pipelines weaving through industrial terrains, line intervention emerges as a proactive strategy crucial for preserving the health and durability of these vital infrastructures. Often synonymous with preventive maintenance, this approach plays a pivotal role in preventing potential problems, streamlining operations, and fortifying against unforeseen disruptions.

Understanding Line Intervention

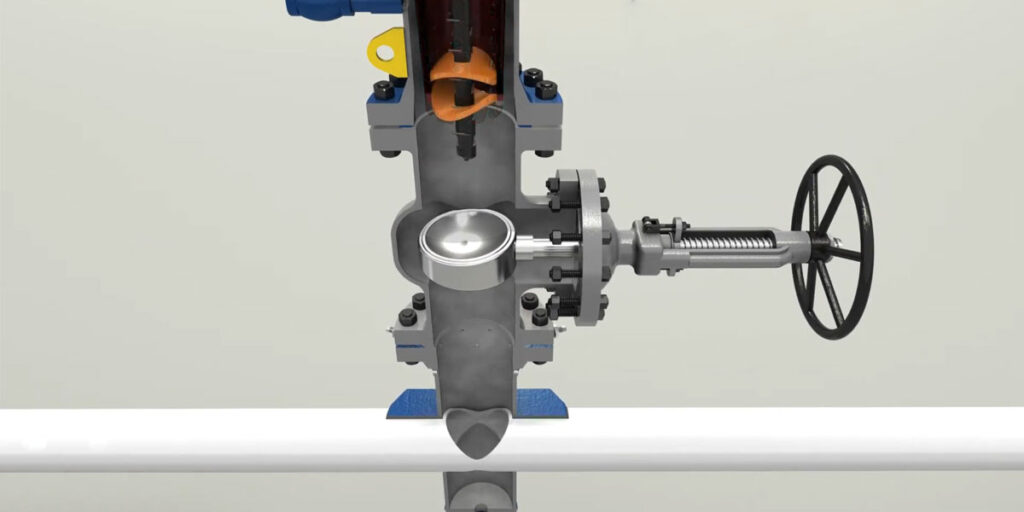

Line intervention encompasses a range of planned activities aimed at preserving and enhancing the functionality of pipelines. This proactive approach involves periodic inspections, repairs, and modifications to prevent potential failures and extend the operational lifespan of the pipeline system.

Key Aspects of Line Intervention in Preventive Maintenance

- Early Detection of Issues: Regular line intervention allows for the early detection of potential issues such as corrosion, leaks, and structural weaknesses. Addressing these concerns in their infancy prevents escalation into more significant problems.

- Optimizing Pipeline Performance: Line intervention encompasses periodic cleaning and maintenance activities to optimize the internal conditions of the pipeline. Removing debris, scale, or sediment helps maintain a consistent and efficient flow of fluids, reducing the risk of blockages and improving overall pipeline performance. Optimization measures contribute to sustained operational efficiency.

- Mitigating the Risk of Downtime: Planned line interventions are crucial for identifying and replacing aging or vulnerable components before they fail. This proactive approach reduces the risk of unexpected downtime, as potential issues are addressed during scheduled maintenance activities. Mitigating downtime ensures continuous operations and prevents financial losses associated with production halts.

- Ensuring Regulatory Compliance: Many industries are subject to strict regulatory standards regarding the maintenance and integrity of pipelines. Line intervention ensures compliance with these regulations, preventing potential legal issues and fines.

- Enhancing Safety: Proactive line intervention contributes to overall safety. Regular inspections and repairs help identify and rectify potential safety hazards, protecting both personnel and the surrounding environment.

Benefits of Preventive Maintenance

- Cost Savings: While the upfront costs of preventive maintenance may be perceived as an investment, they pale in comparison to the potential costs associated with reactive repairs, downtime, and environmental remediation.

- Increased Reliability: A well-maintained pipeline experiences fewer unplanned outages, leading to increased reliability in transporting fluids. Preventive maintenance measures, such as routine inspections and timely component replacements, contribute to the consistent and dependable operation of the pipeline. Enhanced reliability is crucial for meeting operational demands and customer expectations.

- Longer Lifespan of Assets: Regular line intervention contributes to the extended lifespan of pipeline assets. This is especially critical in industries where infrastructure represents a significant capital investment.

- Environmental Stewardship: Preventive maintenance aligns with sustainable practices by minimizing the environmental impact of pipeline failures. Timely interventions prevent spills and leaks that could harm ecosystems and water sources.

In the dynamic field of industrial operations, where time is crucial, and reliability is non-negotiable, line intervention stands out as a valuable strategy. By adopting a proactive mindset towards maintenance and understanding the importance of regular interventions, industries can effectively tackle the challenges of managing complex pipeline systems. This not only ensures resilience but also promotes sustainability. In essence, timely interventions not only prevent potential issues but also contribute to the smooth flow of progress.

Elevate Your Pipeline Performance with TEAM’s Expert Line Intervention Solutions

Ready to elevate your pipeline maintenance with the industry’s leader in hot tap and line intervention? Choose TEAM for safe, innovative, and effective solutions that ensure uninterrupted operations. Our decades of experience, commitment to continuous improvement, and industry-first achievements make us the go-to provider for pressure isolation products and services. Contact us today to explore how TEAM can optimize your pipeline performance and minimize costly and inconvenient outages.