Ready to Get Started?

Send us information on you, your company and your project. One of our experts will respond as soon as possible.

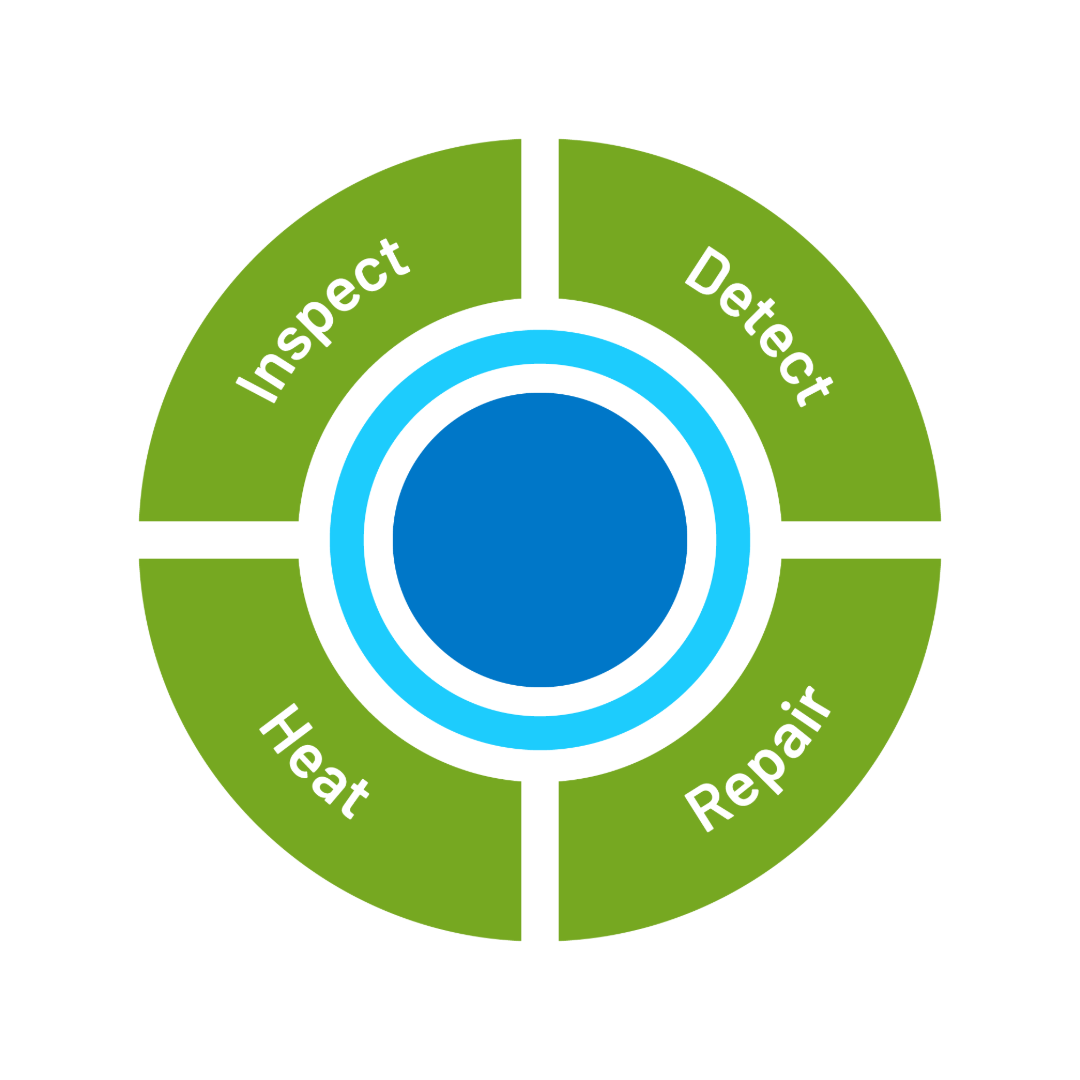

We don’t just check boxes. We connect the dots. TEAM360 unites top-tier technicians, advanced robotics, and real-time digital insight to eliminate handoffs, guesswork, and gaps in your asset strategy. Found a flaw during inspection? Repair360 is already en route. Wrapped a fix? Heat360 locks it in with precision thermal treatment. Every phase supports the next—so you move faster, decide smarter, and extend asset life without compromise.

At TEAM, we don’t do generalists. Every technician is service-certified and field-tested, whether it’s advanced NDT, PWHT, or high-risk on-stream repair. Backed by AWS, API, NACE, and ASNT credentials, our crews bring 50+ years of performance and global reach to every project. From pipelines to process plants, we show up with the right skills, tools, and standards—every time.

With one TEAM that specializes in every facet of asset health, less is lost in translation, more is accomplished, and every move builds safer, faster, and more reliable outcomes.

You can’t improve what you don’t know is broken. TEAM’s Inspect360 provide meticulous asset health insight in the hardest-to-reach places. We combine one of the industry’s broadest inspection portfolios with expert-certified technicians and technologies built for complex environments. From tanks and valves to welds and wall thickness, we turn uncertainty into action-ready intelligence.

Services:

Leaks, emissions, and invisible losses don’t just cost you — they complicate compliance. Detect360 equips you with early-warning systems that pinpoint problems before they escalate. Our field-proven tools and expert teams help you detect fugitive emissions, locate gas releases, and take decisive action—all while supporting your integrity, safety, and sustainability goals.

Services:

Repair360 delivers engineered, code-compliant fixes that keep your assets running without taking them offline. From leak sealing and valve repair to composite wraps and field machining, our on-stream solutions are built to perform — fast, safe, and right the first time. We design and execute on-stream repairs that protect uptime and extend asset life without the delays of shutdown or replacement.

Services:

After you’ve found and fixed the defect, the Heat360 ensures asset integrity stands the test of time. Our heat treatment services reduce residual stress, restore material properties, and future-proof critical components. Whether it’s PWHT, annealing, or monitored bake-outs, we apply precision heat — where and when it matters most.

Services:

OneInsight® is the digital command center that connects our TEAM360 from inspection to heat treatment to advanced asset and project solutions. It serves as your single source of truth — digitizing every touchpoint across every process phase. From live dashboards and audit logs to connected workflows and mobile reporting, our platform turns data into educated decisions.

Tools:

When the work gets tricky, we get creative. From rope access and engineered lifts to turnkey turnarounds, we solve complex problems and boost performance across every TEAM360.

Services:

From à la carte to 360° asset integrity life cycle support, our TEAM does it better.

A: By staying with you from first flaw to final QA, TEAM360 builds context across every phase of the asset lifecycle. That means smarter decisions, fewer surprises, and repairs that last longer—because every action is informed by what came before.

A: We’re built for that. TEAM360 includes Advanced Asset and Project Solutions like rope access, engineered lifts, robotic inspections, unmanned vehicles, and remote monitoring. Whether it’s confined space, extreme heat, or elevation challenges, we bring the tools and teams to get it done safely.

A: We operate across North America with local crews ready to respond. Many of our services—including leak sealing, hot tapping, and heat treating—can be mobilized same-day depending on the location and scope.

A: Absolutely. Our Detect360 is purpose-built to support emissions control, leak detection, and data logging for environmental compliance. We also provide full documentation trails through OneInsight® for audits, QA, and reporting.

A: Yes. TEAM360 isn’t just reactive—it’s proactive. Our asset integrity experts can help build long-term programs using predictive analytics, inspection insights, 3D Laser Scanning, and real-time monitoring data to reduce risk and optimize performance.

A: Yes, OneInsight® was created to seamlessly supplement every phase of TEAM’s asset integrity management. From digital inspection logs and real-time emissions tracking to thermal cycle validation and repair documentation, our OneInsight platform can assist with this. Additionally, the implementation of Digital Twins that connect to OneInsight can provide accurate visualization of the locations for our integrity management data. You get connected insights, automated workflows, and live dashboards that bring clarity and control to your entire asset strategy—no matter where you start.

A: Pipelines, power plants, refineries, chemical facilities—you name it. Our solutions are built for high-risk, high-complexity environments, and we’re equipped to handle scopes from single-component interventions to full-plant turnarounds.

We understand the value of your time, money, and peace of mind. Our team of experts is ready to guide you through the process of integrating services that streamline your operations, reduce unnecessary costs, and eliminate the stress of managing multiple vendors.

Get StartedSee how TEAM Inc. is raising the bar for environmental stewardship, safety, governance, and community impact. Our 2024 Sustainability Profile details the practices, data, and real-world results behind our commitment to a safer, more sustainable future. Download the full report today to learn how our people, processes, and partnerships keep critical industries moving responsibly — and why sustainability is at the core of everything we do.

View the 2024 ProfileSend us information on you, your company and your project. One of our experts will respond as soon as possible.